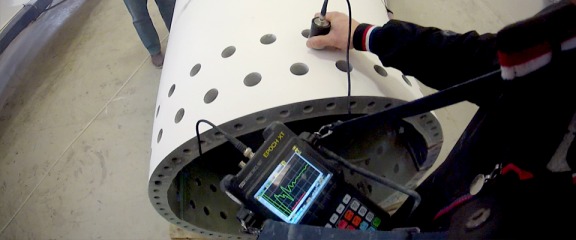

Ultrasonic analysis

Linset has expanded its range of Non-Destructive Testing methods through the use of ultrasonic technology, which has become a quality control standard in the field of dimensional analysis and structural integrity verification of artifacts.

The technique of measuring thickness using ultrasonics is now required and often mandated by numerous prevailing regulations in various sectors (such as the “Rules for the Classification of Pleasure Yachts” published by RINA, for example).

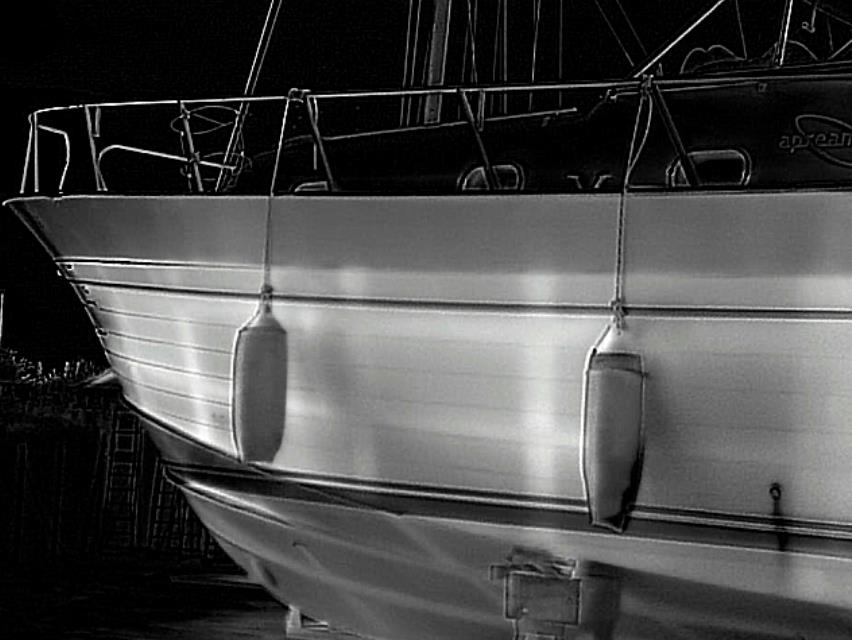

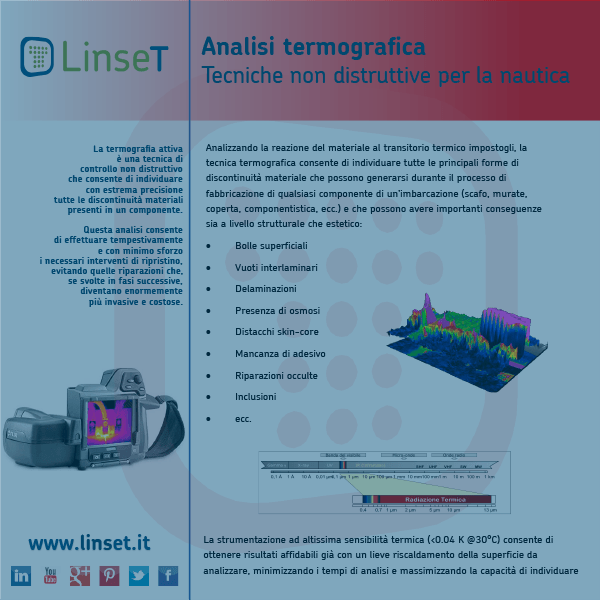

Thermography

Thermography is a non-destructive testing technique that allows for precise detection of all material discontinuities present in a component.

This analysis enables prompt and minimally invasive interventions to be carried out when necessary, avoiding repairs that would become much more invasive and costly if conducted at later stages.

For instance, a typical application involves detecting voids within the skin-coat layer: this defect is quite common (especially when the skin-coat is applied manually) and relatively easy to address during the bodywork phase. However, if left unaddressed, it could potentially damage the final paintwork (resulting in substantial restoration costs and image-related issues).

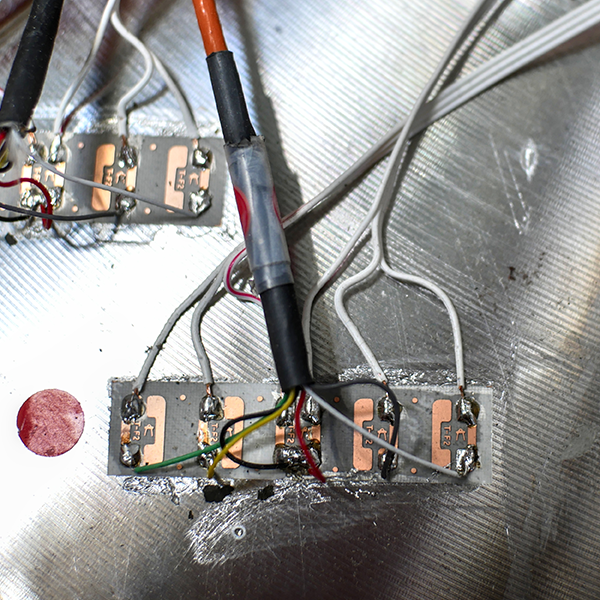

Strain Gauging

Strain measurements are a non-invasive analysis methodology used to assess the state of materials and structures of various kinds under operational or stress conditions.

The utility of strain measurements lies in the ability to accurately monitor mechanical deformations of the analyzed object that would otherwise go unnoticed.